What is clay?

|

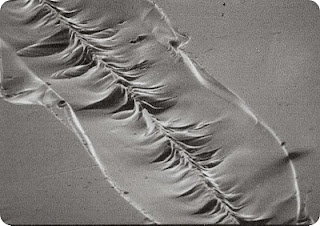

| Flat plates of clay particles |

Before choosing your pottery clay body it is first important to understand a little about clay and why it is used as a component of a clay body. Clay is a mineral extracted from the ground which can be readily moulded like plasticine. At microscopic level, the particles of clay have a flat plate-like structure giving them this plastic like property. The 2 most commonly used pottery clays are Ball Clay and China Clay (Kaolin). Ball clay tends to be very plastic-mouldable but off white in colour. China clay is less plastic but has a whiter fired colour. Many other clays are available but they tend to be off white to red in colour and therefore less used in high volume white pottery manufacture.

What is a clay body?

The terms clay and body are used by potters almost interchangeably. However in most cases it is not technically correct! In simple terms

a body is a formula containing clay and other minerals. Therefore clay is a raw material component of a body. In past times a body was simply a clay dug from the ground which was variable in both its composition and properties. However, modern commercial potters no longer rely on bodies manufactured from clay alone. To achieve specific properties they are scientifically formulated in a very precise way.

A wide range of raw clays and minerals are used from all around the world. They vary in colour, strength, particle size as well as mineralogy and purity. No two clays from different parts of the world are precisely the same although for comparison purposes they can act in a similar way when used as part of a body formula. For studio pottery manufacture coarse minerals called grogs are often added to the clay body formulas to give additional texture appeal and improved properties.

How to choose the best clay for you

Firing range of your kiln

The maximum firing temperature of your kiln should be your first consideration when deciding which type of clay body to buy. It is no use choosing a stoneware clay firing 1250 C if your kiln will only fire to 1200 C. Lower temperature kilns are suitable for earthenware and terracotta bodies (less than 1200 C) whereas high temperature kilns are acceptable for most bodies including porcelain and stoneware.

Colour

The fired colour of the body will often dictate the cost. In general whiter clay bodies are more expensive than buff or cream coloured ones. The type of clay body you use is often prescribed by your colour selection. For example porcelain and bone china are always very white after firing. To give you an idea of the fired colour produced by the different clay body types see the section entitled 'range of bodies'. Please also note that the firing temperature has a significant affect on the fired colour!

The making Process

The making process you intend to use to shape the body is also an important factor when considering the most appropriate clay body. Clay body sub-types allow you to select a clay suitable for all major forming operations including throwing, hand-building, sculpting, casting or machine making.

Size of your work and end use

The size of the pottery piece you plan to make is also important. Larger pieces often require a more heavily grogged (less plastic) clay whereas smaller pieces of work can require more plasticity. In addition, the end use of the ware, whether it is purely ornamental, for outside use, or designed as functional tableware will affect your choice of clay body.

Texture

For the more experienced potter the texture of the clay body after firing is often important.. The feel, look and strength of the ceramic piece is strongly affected by this sub-type of clay. For example the grogged subgroup of bodies generally add texture, strength and stability, whilst an ungrogged body will result in a smoother more polished finish.

Glaze compatibility

Whichever clay body you choose it is imperative that you select a glaze which is compatible with the body. This technical compatibility is critical to producing an intact piece without faults after firing. Be guided by your supplier who can supply compatible glazes for most body types and firing schedules. For peace of mind you should always test a sample of the glaze and clay body in your own kiln prior to any major production. The temperature and firing schedule of your kiln will influence whether your clay body and glaze are compatible after firing.

Range of Clay Bodies

The are numerous clay bodies produced commercially around the world available to the craft potter, studio potter and commercial pottery. Indeed there are so many that it is impossible to detail them all here. Bodies are often developed to make them suitable for the making process. Therefore suppliers often state subtypes which define which clay bodies are more suitable for hand throwing, casting, hand building etc.

Clay bodies however can be classified into a relatively small number of categories according to their colour, firing range and texture. Below are a few major examples showing the fired colour of individual body types.

|

| Porcelain |

|

| Bone China |

|

| Earthenware |

|

| Stoneware |

|

| Terracotta |

Bone China

|

| Bone China |

This is a smooth textured extremely white firing body that is also translucent. It is unique in that it contains a high proportion of calcined bone ash . Biscuit firing at approx 1220 C gives it a high strength making it suitable for producing delicate highly decorative items as well as tableware. This type of ware after glazing is often decorated with onglaze colours or precious metal decoration to create stunning pieces of pottery. Electric firing kilns usually produce the best bone china quality.

Porcelain

This is a smooth textured translucent extra white firing body similar to bone china. However two types of porcelain are made, a 'hard porcelain' which requires a glaze firing in excess of 1400 C and a 'soft porcelain' which requires a glaze firing to approx 1250 C. Biscuit firing however is often around 1000 C which allows pieces to be glazed more successfully. High temperature gas kilns are often used to fire this type of body. Porcelain, like bone china, can also be decorated with onglaze enamels and precious metal to create delicate highly attractive giftware as well as tableware.

Stoneware

|

| Stoneware |

This class of clay body is commonly used by craft and studio potters. It has a relatively high biscuit firing temperature in excess of 1150C. Many commercial bodies, available in a range of off white to buff colours, are fired in the range 1250-1300C to give maximum strength. By glazing with a reactive type coloured glaze a wide variety of effects and colours can be achieved. Because of this stoneware has found high popularity with craft potters looking to create unique coloured or or textured hand made pottery. This body type can be used to produce both decorative and functional pieces such as tableware.

Terracotta

|

| Terracotta |

This class of body is typified by its unique red terracotta colour. This clay body has a high iron content in its mineral components giving the unique red colour. Like stoneware the smooth texture can be modified, by addition of grog (coarse material), to give a much rougher finish. Terracotta bodies have a relatively low firing temperature of 1000-1050C and are therefore porous and have relatively low strength after firing. Commonly unglazed it is often used for sculptures, planters, tiles and garden ware where the technical properties are not so demanding. For more demanding environments such as tableware the body is often glazed to give a stronger more durable product.

Earthenware

This type of body is often used for hand painting by hobbyists.

For craft pottery this body is biscuit fired to approx 1000 C to allow easy brushing of underglaze colours or coloured glaze on to the porous surface. Following glaze firing to 1050 C to 1150 C the body colour and underglaze colours show through the transparent glaze producing highly decorative ware. After glaze firing the body remains porous with reduced strength compared to fully vitrified bodies like porcelain or bone china.

Body colour ranges from white to buff and some bodies are also grogged to provide texture.

For commercial tableware optimum body strength is achieved by firing the biscuit in the range 1180-1220 C but this peak is not often needed for lower strength or decorative only ware.

Special bodies

This range of bodies include, highly coloured bodies, low firing bodies, Raku bodies, and special highly textured bodies. In the case of Raku the body is modified to allow rapid heating and cooling without cracking, usually by the addition of grog. Making raku pottery successfully requires more expertise than other pottery types and often depends on a trial and error approach. To learn more about Raku read my separate article on

Raku making.

Summary

Clearly, choosing the right clay body for you poses a number of technical questions. It is more difficult than is immediately obvious. However I recommend you talk to your clay body suppliers in the first instance and not just search the internet. Their vast knowledge of their products will make the whole process of selection of suitable body and glaze just that much easier.

Good Luck

Happy potting!

The Potters Friend

More information and other technical articles on pottery and ceramics can be found at my website

The Potters Friend.

.jpg)

It is a common occurrence for mugs used everyday to become badly stained by tea or coffee. The brown stains are unsightly and difficult to remove. Sometimes they become so bad that scrubbing in soapy water does not remove them. Clearly coffee and tea are strong staining agents!

It is a common occurrence for mugs used everyday to become badly stained by tea or coffee. The brown stains are unsightly and difficult to remove. Sometimes they become so bad that scrubbing in soapy water does not remove them. Clearly coffee and tea are strong staining agents!